ReactPro

The combination of the injection of a thermoplastic and a polyurethane obtained by RIM (Reaction Injection Molding)

ReactPro

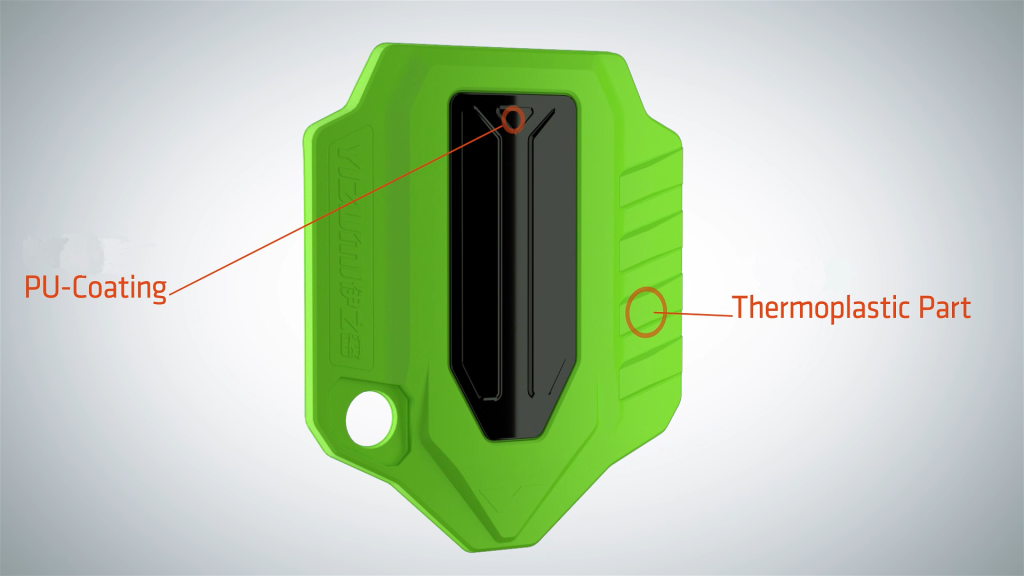

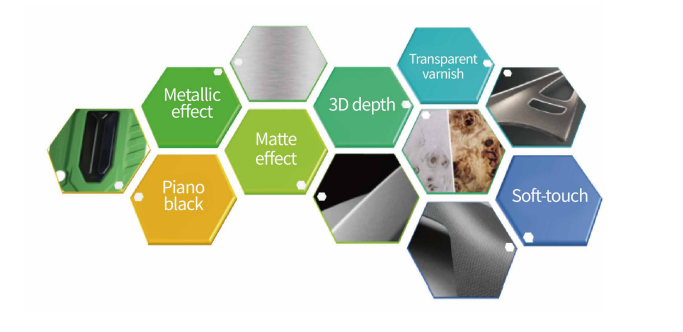

Yizumi ReactPro introduces polyurethane reaction molding technology into the injection process to achieve a perfect surface in one step by applying a polyurethane coating to the surface of an injection part.

The integration of thermosetting polymers such as polyurethane for the production of rigid parts which have good heat resistance without deformation that can be painted directly on the production lines (trims, bumpers, parts under the engine hood, etc…)

ReactPro

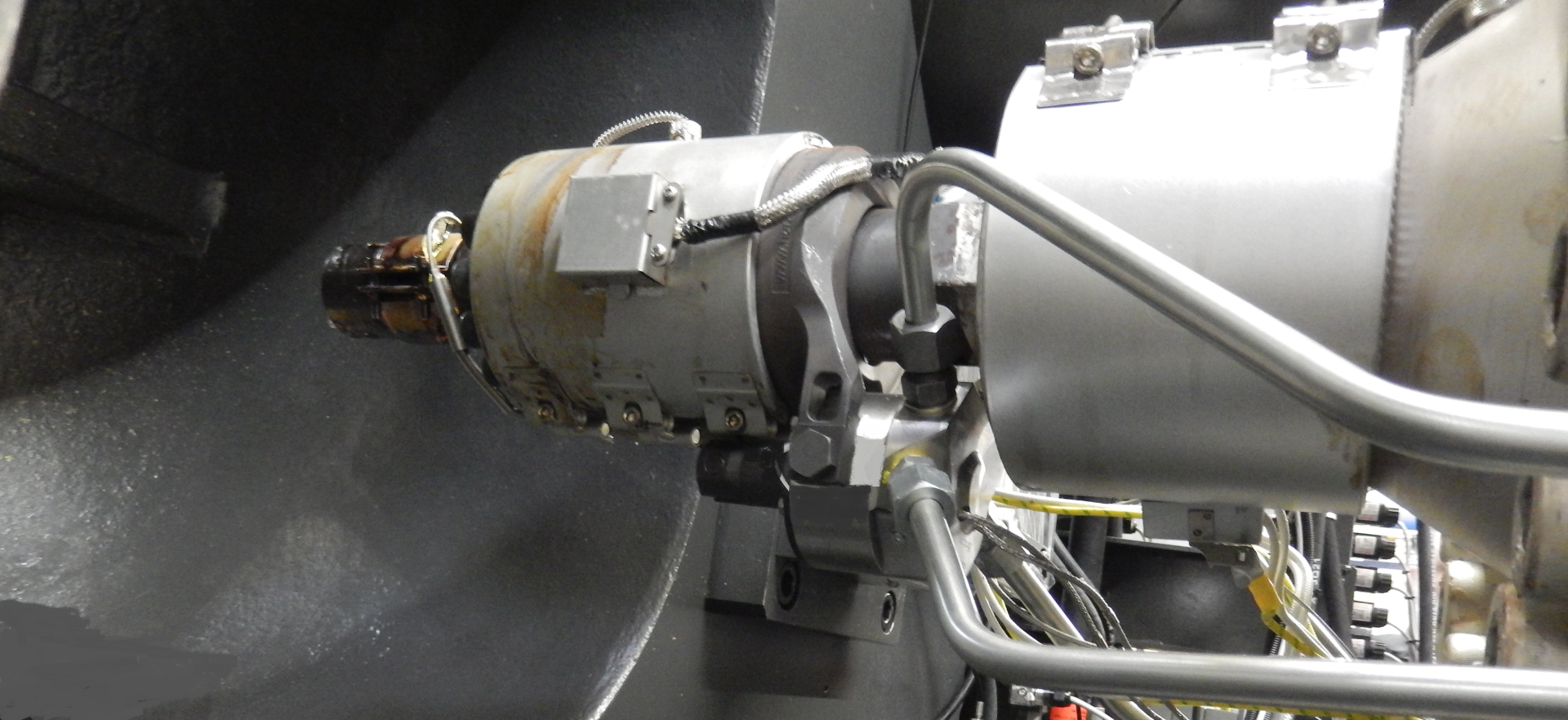

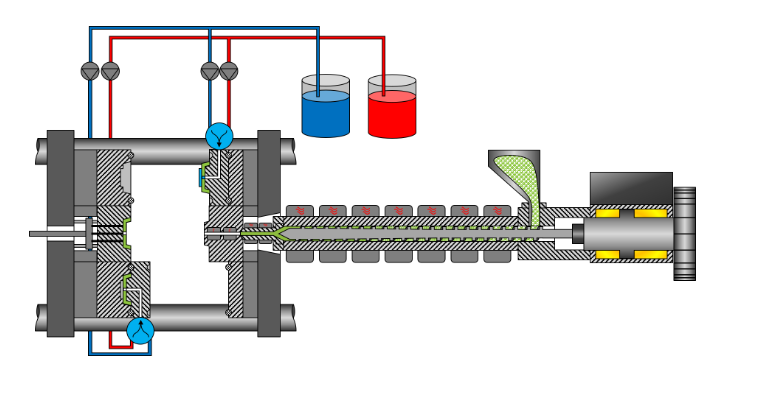

The heart of ReactPro technology is the chemical reaction between two liquid components isocyanates and polyols.

These two components are stored respectively in tanks and then precisely dosed in measuring units and then conveyed into the mixing head under high pressure. The mixing head valve opens to allow reactive liquids to enter the mixing head cavity under 100-200 bar pressure and be mixed well through high-speed impact force. The liquid then flows from the mixing cavity into the mold at approximately atmospheric pressure. The liquid enters an exothermic chemical reaction inside the mold and produces polyurethane polymers.

ReactPro

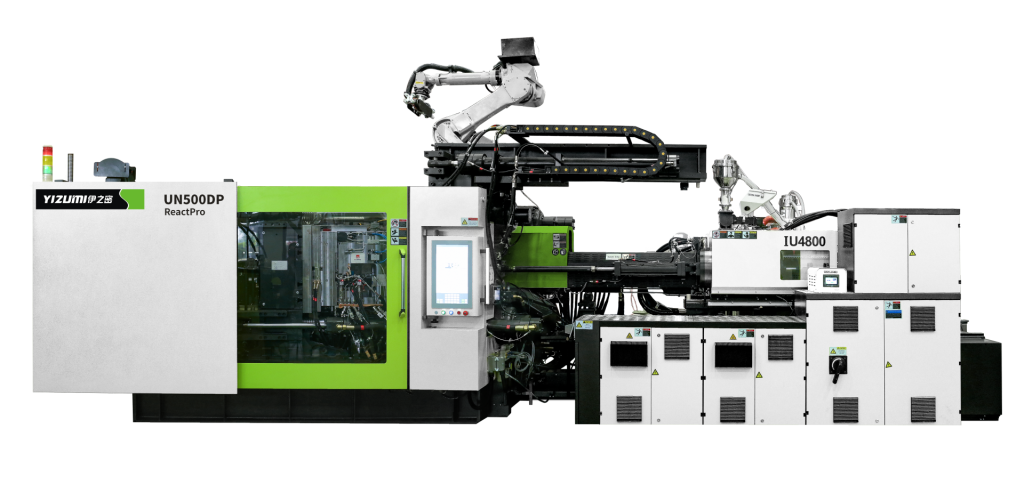

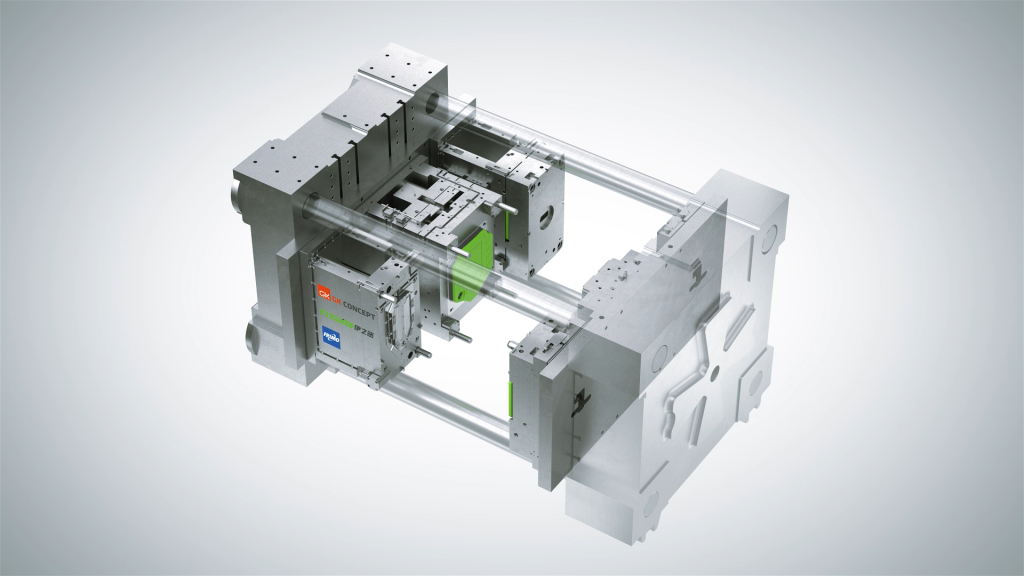

The Yizumi UN500DP two-platen injection molding machine integrates a PU RIM injection system and “1+2” tool, allowing molding in a single phase of an engine cover composed of a thermoplastic part and a polyurethane part.

En images

Do you need information?

Do not hesitate to contact us.