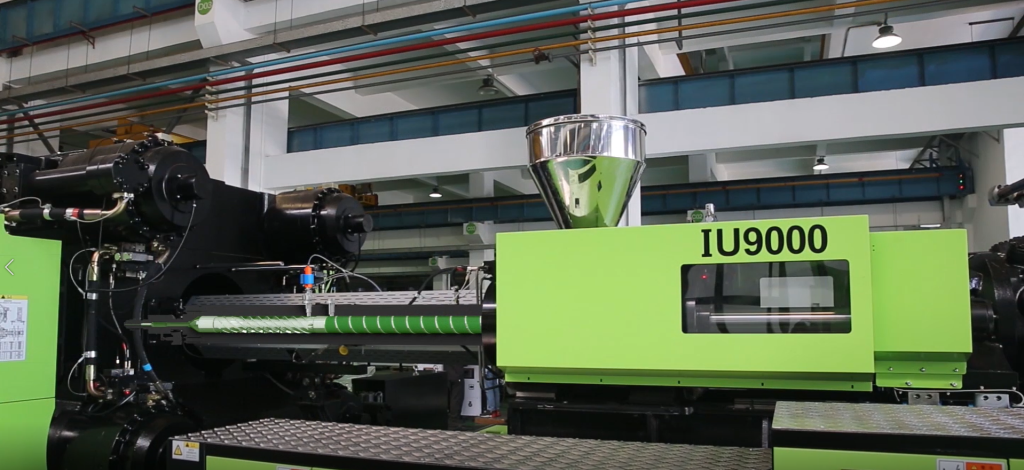

ChemicalPro & FoamPro

Lightening of materials by ChemicalPro process or by MucellPro process.

FoamPro-Chemical

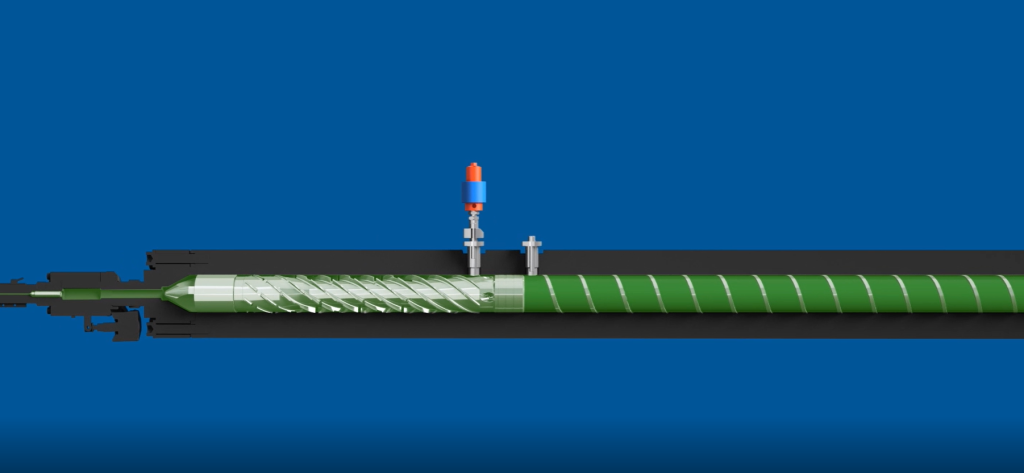

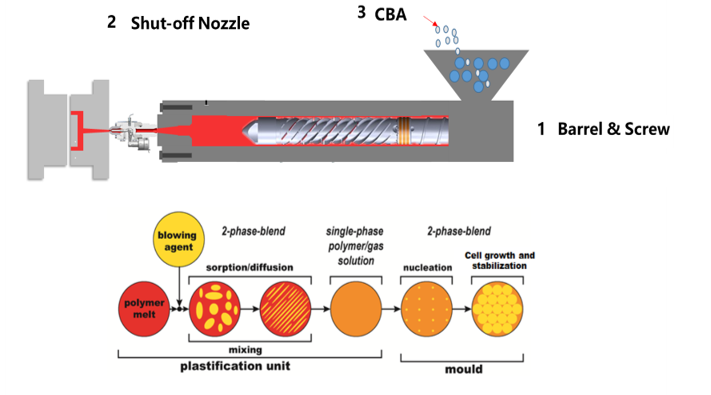

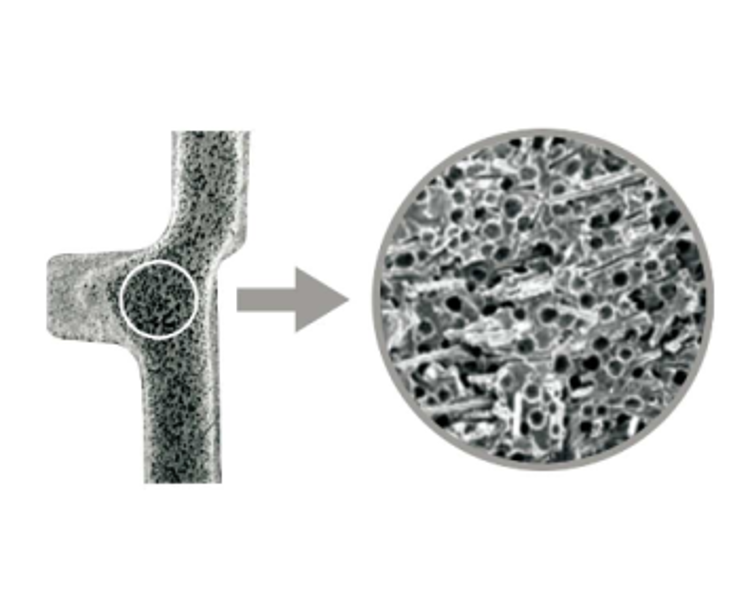

Chemical foaming is a technology that adds a certain percentage of chemical foaming agent (usually a thermally decomposing foaming agent that releases CO2 when broken down under heat). It is then injected into the plasticizing unit in order to be mixed before injection into the mold cavity. The foaming agent creates micro cells in the plastic product through heat and internal pressure diffusion to create a plastic product with a uniform internal foaming structure and a strong skin layer. The bubble cell diameter can be kept within the range of 10 to 100μm.

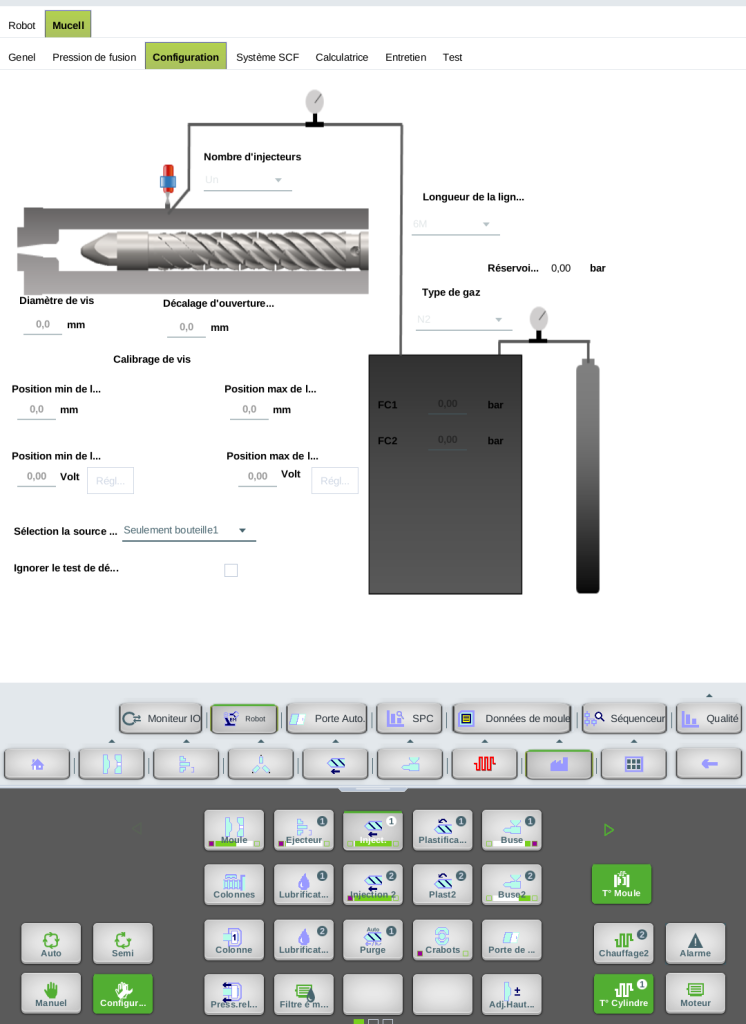

FoamPro Physical

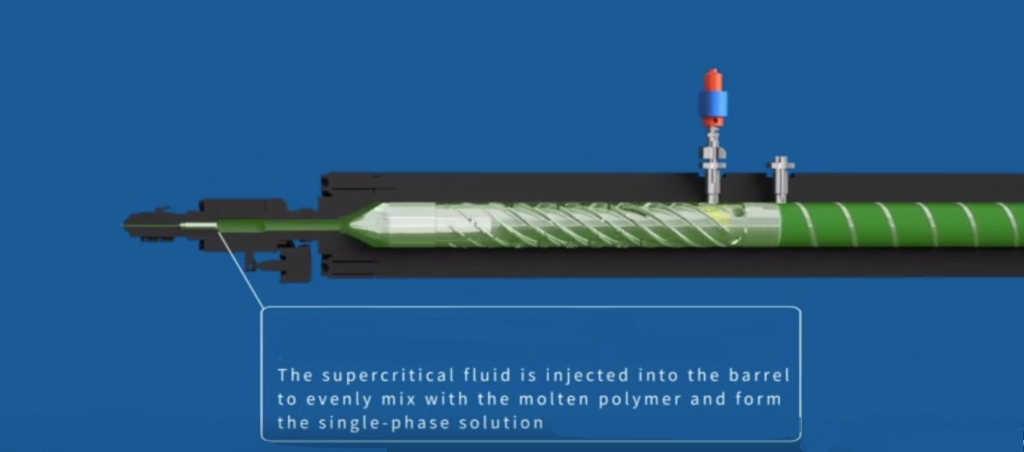

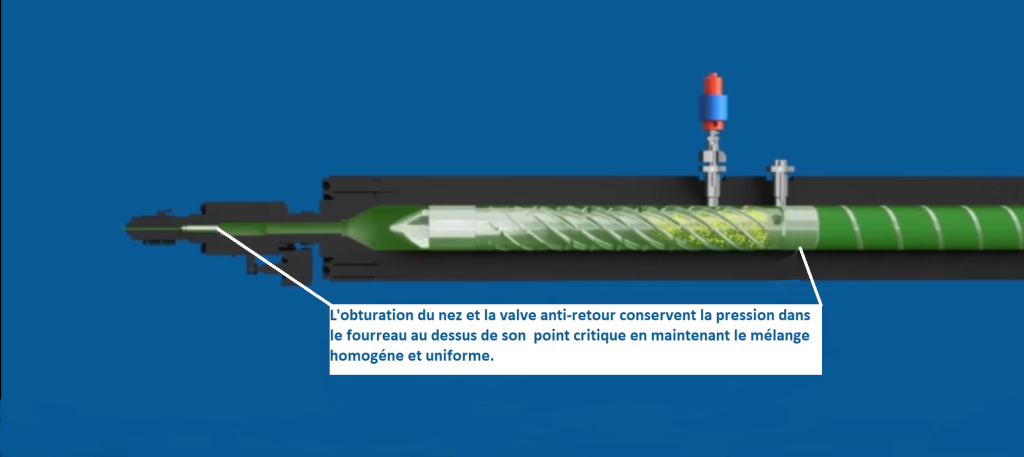

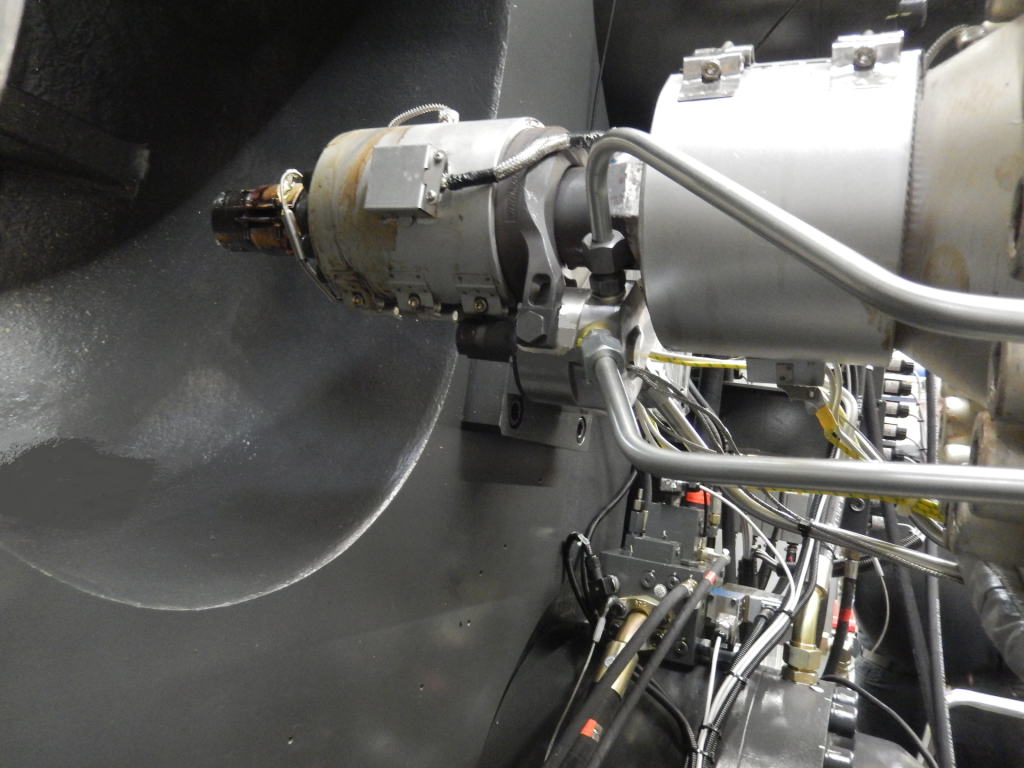

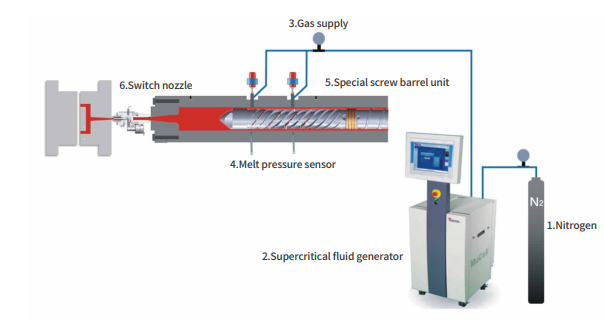

Physical foaming is a technology for supplying gas (Nitrogen) injected into the plasticizing screw during the injection phase in order to mix it with the molten plastic material and form an homogeneous mixture. It is then injected into the mold cavity. When the pressure is released, the gas forms a honeycomb structure inside the plastic product. The micro cells take the place of the polymer, allowing a saving in material weight and the structure also makes it possible to increase the mechanical resistance of the part.

– 20% reduction in part weight.

– Reduction in cycle time by 15-30% increasing production capacity and reducing costs.

– Reduced viscosity for better filling.

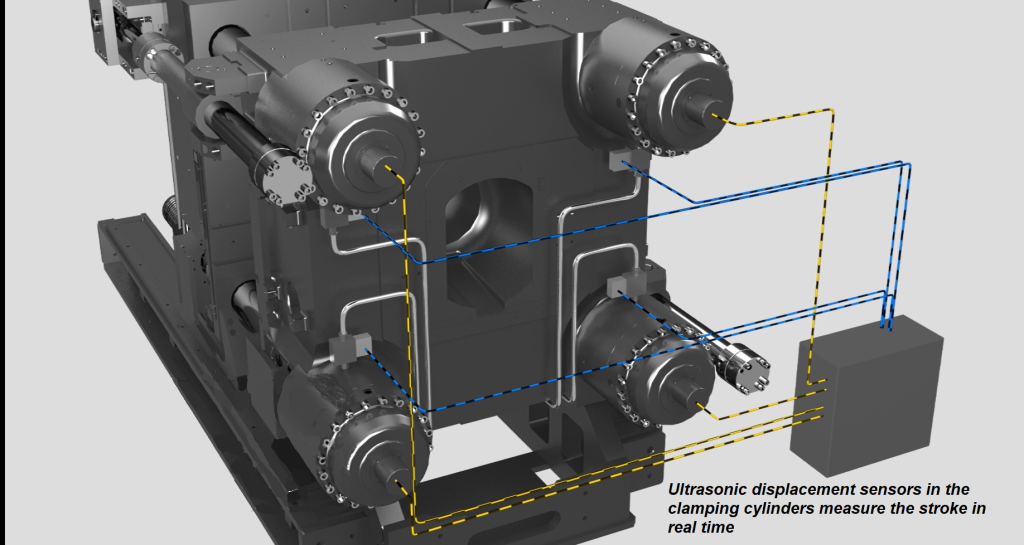

– Reduced clamping force by 30-50%.

– Reduction of sinkholes and improvement of appearance.

– Reduced shrinkage and internal tensions.

– Reduction of deformations.

– Improved mechanical resistance.

– Reduction in injection pressure leading to a reduction in energy consumption and an increase in the lifespan of the mold.

Chemical&FoamPro

Mucell process for food packaging parts realisation.

En images

Do you need information?

Do not hesitate to contact us.